Benefits

- no reclamation due to wall thickness

- no faulty rejects

- hardly any maintenance costs

Contactless

Measuring Principle

The device works

contactless. A light line is projected onto the glass surface. The

reflections at front and rear side of the glass are displayed on CCD

line sensors and their distances are evaluated.

Structure and Installation

The device consists of a measuring gauge head, measuring electronics as well as instruments for positioning of the gauge head.

Installation can be done by using an available testing station with a rotation station, for example CO or TIM machines.

The measuring

electronics generates an output signal if the wall thickness is below

the minimum tolerance, which is transferred to the control of the

available selection machine.

Adjustment

The adjustment after job

changing isn't complicated at all and is carried out within a few

minutes. Measuring height, distance and inclination of the sensor to the

container surface are to be adjusted.

The adjustment procedure is

supported by a number of displays and service functions from the

electronics.

Advantages

- Measurement is possible for round and many non-round containers.

- The device measures a spot and does not supply the average wall thickness from a relatively large area like the known contacting devices. Narrow, restricted, thin areas (bull eyes) will be rejected.

- In many cases, measurement in the area of engravings is possible.

- Available rotation stations can be used, a special thickness inspection machine is not necessary.

- No limitation of the testing speed.

- No wear as usual at known contacting devices

- Stable measurement,

no drift. No further calibration.

Damages of the container are out of the question.

Measuring range

0,4 ... 5,0 mm

Accuracy

0,1 mm

Measuring frequency

3.000 measurements per second

Testing speed

up to 300 containers/min

Sensor dimensions

110 * 185 * 25 mm (height * depth * width)

Measuring distance

15 mm

Distance tolerance

+/- 4 mm

Output

numerical display, 3 digits

selection signal, potential

free

Service functions

LED bar-graph for measuring

gauge head distance Display of the valid measuring values for a

container each

Input

signal for rotation time of

the container

for example G1 at the CO -

machine

Measuring principle

double reflection method

Light source

halogen lamp, 6 months

continuous operation

Sensor system

2 reverse direction ray

systems

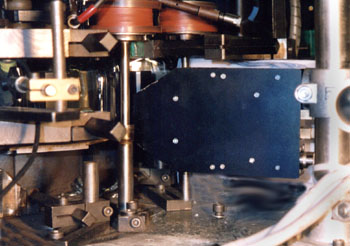

TM(C) 15 installed at a

CO-machine during inspection

of non-round containers

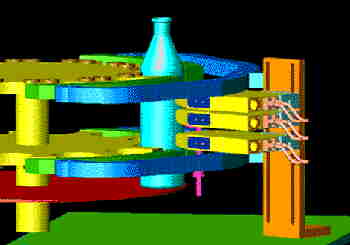

TM(C) 15 - top view

TM(C) 15 as 3-sensor-version

for the measurement

of round containers

TM(C) 15 as 3-sensor-version

at a CO-maschine