The lap sensor is used for the detection

o the lap which occurs between the two parts of the mould at stem ware.

It is particularly used at fire polishing

machines.

Measuring Principle

The device is based on light sensitive sensors. The bottom of the stem glass is penetrated with light. This is done when the item rotates in a rotation station of the fire polishing machine. The light transmitter and the receiver are located above and underneath the bottom plate.

When the lap passes the light sensitive area of the sensor, the intensity of the light which is received changes considerably. By comparison with thresholds, a signal is sent out at this moment.

Structure

The device comprises the following components:

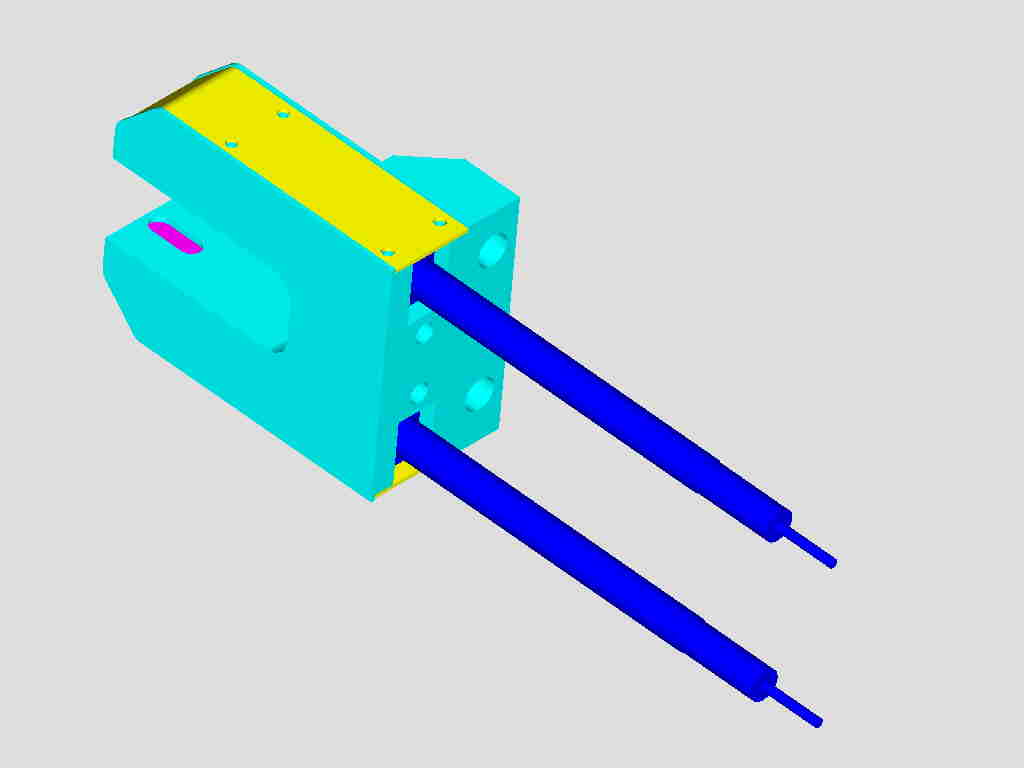

- sensor head with light transmitter and receiver

- water cooling of the sensor head

- electronic unit comprising the electronics for the transmitter, the receiver and the signal processing

Operation

Special emphasis has been placed onto a simple operation of the equipment: the sensor head has to be set to the dimensions of the new glasses during the job change procedure. This can be done in a simple way by visual estimation due to the robust design of the sensor. The only essential operation is the teaching of the thresholds. It is supported by the digital displays of the electronics.

Specifications

- Reaction time: 250 µs

- Voltage: 24 V DC

- Output signal: 24 V DC

- Output pulse length: 40 ms

- reliable detection

- no disturbance by glass defects

- fast job change procedure

Sensor head, installed in a

fire polishing machine

Drawing of the sensor head in

principle;

the sensor cables are indicated

at the right.

กก