This is being done on a conveyor belt.

- to measure the axis of bottles

- to control the tolerances

- to sort out faulty containers

- to process the measured values and provide statistics.

Measuring

Principle

The mechanical and optical part is similar

to the device IDM(C):

The bottles are illuminated through their

bottom by some LED- light sources as far as a measuring position is

reached, which is determined using a further camera at the bottom. A

special lens projects the image of the neck onto the optoelectronic

receiver.

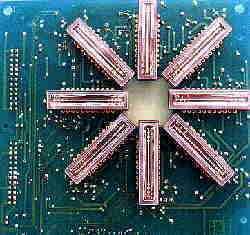

It is designed on the base of some CCD-row

sensors.

The output signals of these sensors are

evaluated in a special microcomputer. It provides the signals to sort

out the faulty containers as well as some statistics. The measured

values are displayed using a special display unit based on LED-diodes.

Structure

The device permits a simple arrangement on

the conveyor belt. The bottle is transported using a bottom belt as well

as the finish support belt at their neck. It is easy to maintain and can

be combined with other testing systems.

Service and

Operation

Particular emphasis was placed on operator

convenience: The installation can be done easily and an adjustment is

not required even after job changes.

Specifications

Advantages

- maximum inside diameter of the neck: approximately 30 mm (standard)

- Speed of measurement: up to 300 /min

- Accuracy of measurement: 0.1 mm

- The device works in a contactless manner without wear.

- There is no need of mechanical gauges.

- Any rotation the bottle is not required.

- The device can be used at bottles with a circular cross section as well as at a wide scale of non-circular containers.

- A measured value, not just a test result passed/not passed is provided. This way trends can be detected as soon as possible.

The opening of the bottle is

displayed at the

sensor star. If it is not in the

center,

the bottle axis is perpendicular.