Automotive

Aerospace

Rail

Inspection of automotive engine blocks and cylinders for internal and external flaws can be

accomplished by Eddy current (EC) techniques.

Inspection of automotive engine blocks and cylinders for internal and external flaws can be

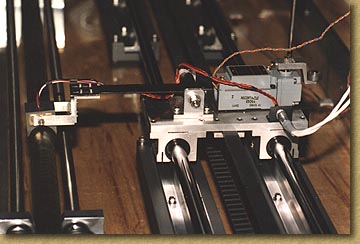

accomplished by Eddy current (EC) techniques.The technique provides for high sensitivity non-destructive examination of conductive materials. EC sensors do not need to be in full contact with tested surface during inspection, and high temperature applications are common. Multi or single test channel equipment can be used not only for surface flaw detection but also for verification of material hardening (softness), heat treatment, conductivity or precise measurements of small distances. The automated test system reliably verifies the integrity of the inner and outer surfaces of an automotive cylinder liner in less than 15 seconds. Inspection of round torsion bars for surface flaws is accomplished using high resolution electromagnetic inspection technique.  The part is examined for surface longitudinal cracks using a semi-automated tester unit. Flaws as small as 0.005" in depth can be reliably detected.  High requirements on quality of friction materials used for manufacturing of automotive brake

shoes can be ascertained by application of automated inspection based on ultrasonic technology.

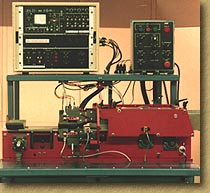

High requirements on quality of friction materials used for manufacturing of automotive brake

shoes can be ascertained by application of automated inspection based on ultrasonic technology.Block Test Machine (BTM) is designed to inspect friction material for delamination and voids. Three roller probes emit sonic waves which penetrate through material thickness. If a flaw is detected the tested piece is chute. BTM can be inserted into a production line or can be used off-line. |